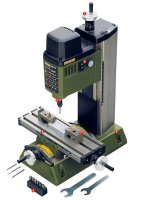

1. Handwheels with zero adjustable scales, 1 revolution = 1mm, 1 division = 0.05mm.

2. Continuously variable speed from 5,000 – 20,000rpm, perfect for even the smallest milling cutter.

3. Cutter clamping in MICROMOT system collets.

4. Table of stable aluminium. Both axes are fitted with adjustable dovetail slides.

5. MICROMOT steel collets, triple slit and hardened, from 1 to 3.2mm.

6. Stable cast iron base.

7. Supplied complete with stepped clamp blocks of steel.

The accurate miller for delicate projects. Spindle speeds 5,000 – 20,000rpm. For work with extremely small cutters.

Stable grey-cast iron machine base, vertical guide and compound table. Free from play, readjustable dovetail gib in all axes. Die-cast aluminium arm housing, with 24-pin special motor (balanced). For vibration-free work at high speeds.

The triple slit, hardened steel MICROMOT collets cover 1, 1.5, 2, 2.4, 3, 3.2mm (1/32, 1/16, 5/64, 3/32, 7/64, 1/8inch). The table is fitted with 3 T-slots of the 12 x 6 x 5mm MICROMOT norm. An adjustable ruler scale eases the positioning of the workpiece.

Technical data:

230V, 100W, 50/60Hz. Spindle speeds 5,000 – 20,000rpm. Table 200 x 70mm with X-Y travel of 134 and 46mm respectively, with vertical travel 80mm. Footprint size 130 x 225mm and overall height 370mm. Weight approx. 7kg.

The clamping blocks depicted are included too, but not the workpiece! (nor are the 3 Tungsten milling cutters NO 27 116)