Get this file: https://www.printables.com/model/420062-raspberry-pi-mount-for-din-rail-bracket-fan-mount

Wanting to mount it however to this: https://aliexpress.com/item/1005002245769197.html

which has different mounting holes (47.5mm versus 52.5mm and, need to be for M4)

1.

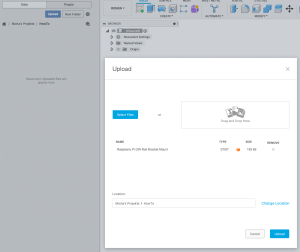

01 Upload STEP File

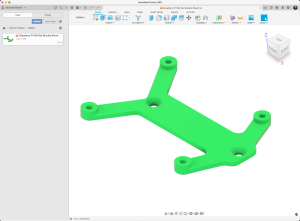

02 Open STEP File

03 To be able to Redo / Undo better “Capture Design History

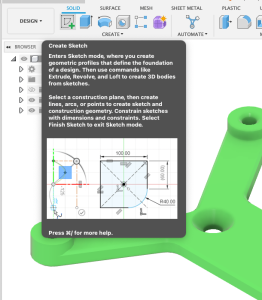

04 Create Sketch

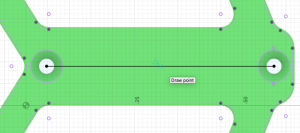

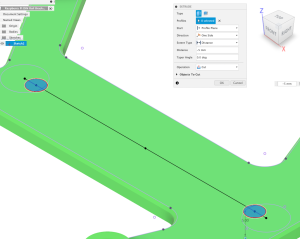

05 Choose the “Main Plane”

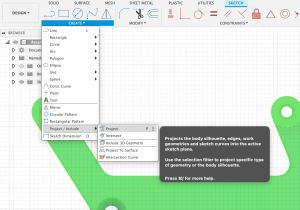

06 Create -> Project

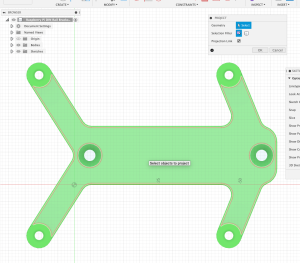

07 Select the same plane again

08 Select Line tool and draw a line between the 2 existing holes

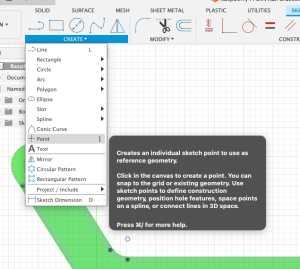

09 Create -> Point

10 Move mouse on the line till a little blue triangle appears – this is the middle of the line. Click to draw a point.

2.

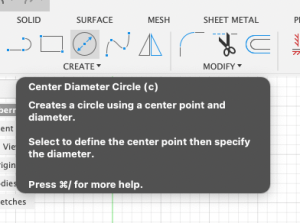

11 Create -> Circle

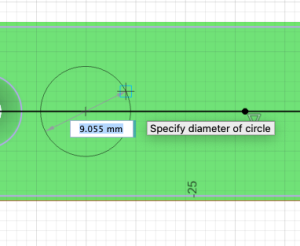

12 Draw 2 circles on the line. One left of the point you created and one right. Diameter set to your needs. For example 4.5 for M4 screw.

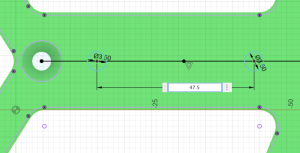

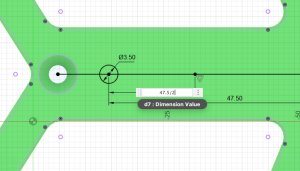

13 Press “D” for Dimension or choose Dimension from menu. Click on both circles and set distance to 47.5

and set distance to 47.5 14 “D” for Dimension. Click on one circle and on the Point we created and set distance to “47.5 / 2” that point is in the middle of circles.

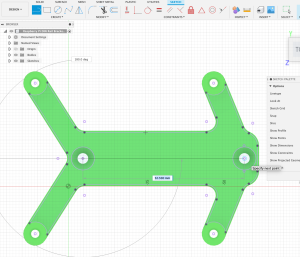

15 Sketch should now look like this

16 Finish sketch

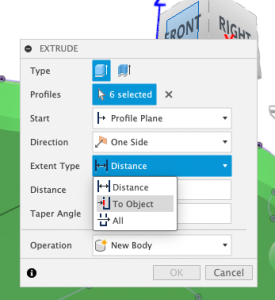

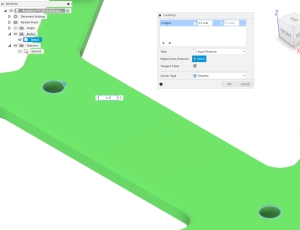

17 “E” for Extrude and select the Area where the original hole is

18 Extent Type “To Object”

19 Flip the model and select the bottom plane

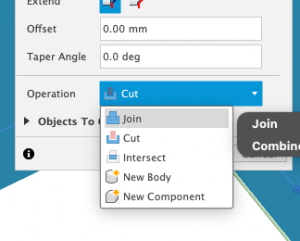

20 Operation “Join” to close the whole. Standard would be cut because Fusion thinks you want to cut.

3.

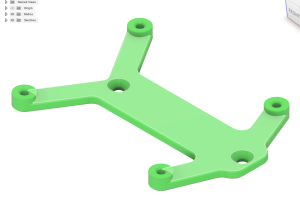

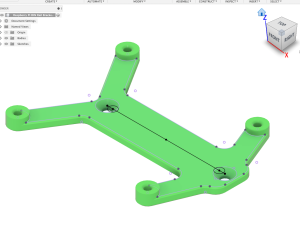

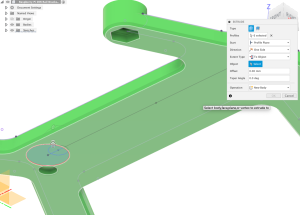

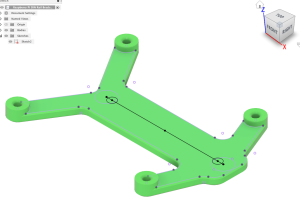

21 Model should now look like this.

22 View the sketch we draw again

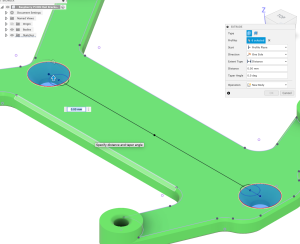

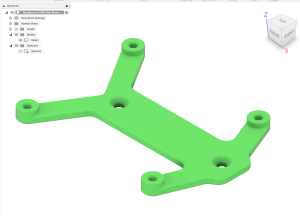

23 “E” for Extrude and select the areas where you want the holes. Distance -5mm. Operation Cut.

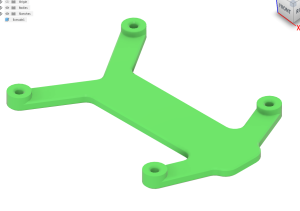

24 Select Chanfer tool from menu and select the upper edges from the holes. For M4 chamfer would be 2mm.

25 Finished part

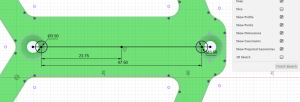

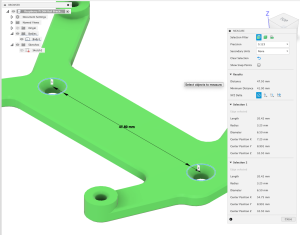

26 To Doublecheck Inspect -> Measure

27 Select the holes. Distance should be 47.5

Huge thanks to Michael Mueller for his screenshots and write-up:

01 Upload STEP File

02 Open STEP File

03 To be able to Redo / Undo better “Capture Design History

04 Create Sketch

05 Choose the “Main Plane”

06 Create -> Project

07 Select the same plane again

08 Select Line tool and draw a line between the 2 existing holes

09 Create -> Point

10 Move mouse on the line till a little blue triangle appears – this is the middle of the line. Click to draw a point.

11 Create -> Circle

12 Draw 2 circles on the line. One left of the point you created and one right. Diameter set to your needs. For example 4.5 for M4 screw.

13 Press “D” for Dimension or choose Dimension from menu. Click on both circles and set distance to 47.5

14 “D” for Dimension. Click on one circle and on the Point we created and set distance to “47.5 / 2” that point is in the middle of circles.

15 Sketch should now look like this

16 Finish sketch

17 “E” for Extrude and select the Area where the original hole is

18 Extent Type “To Object”

19 Flip the model and select the bottom plane

20 Operation “Join” to close the whole. Standard would be cut because Fusion thinks you want to cut.

21 Model should now look like this.

22 View the sketch we draw again

23 “E” for Extrude and select the areas where you want the holes. Distance -5mm. Operation Cut.

24 Select Chanfer tool from menu and select the upper edges from the holes. For M4 chamfer would be 2mm.

25 Finished part

26 To Doublecheck Inspect -> Measure

27 Select the holes. Distance should be 47.5