After not liking some elements of the first lathe I got, the Emco Unimat 4 I went looking for another one, that did have those features or differently than this Emco, while still being quite small in size, but not capability.

An Emco Compact 5 was an option, cause it could also do threading, but most for sale were too expensive for their age/usage and not a lot were offered anyways. The 2 major other ones were Sherline and Taig (also known als Peatol or Grimberg) and even if Sherline also makes a lot of stuff in metric, you just don’t see them sold in EU much, Taig however, even if not metric, was. And then I found one.

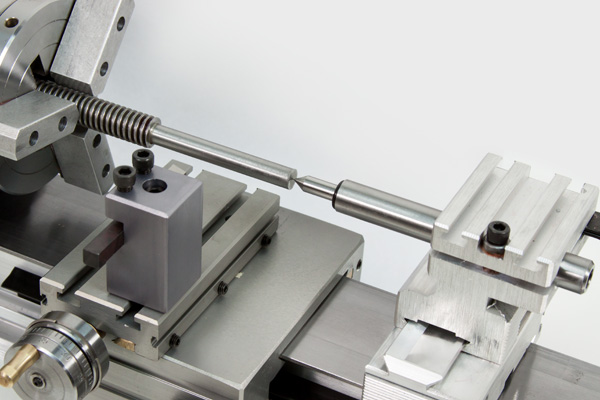

fully functional ad pic

with lots of useful accessories, so it seemed…

but that motor was ‘rough’

and did not have an automagic powerfeed so I got a new one

which broke in transport

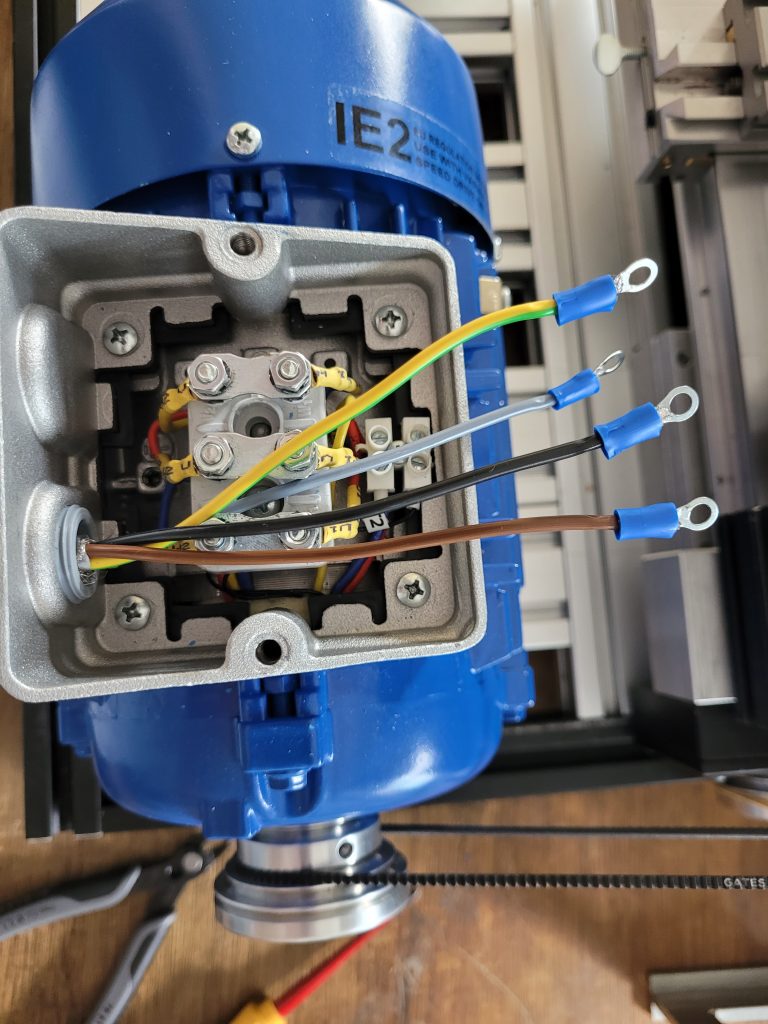

got a new 4 pole 3ph 0.37Kw/0.5HP 230V motor

got a proper 0.75Kw/1HP VFD 2ndhand, 230V 1ph to 3ph

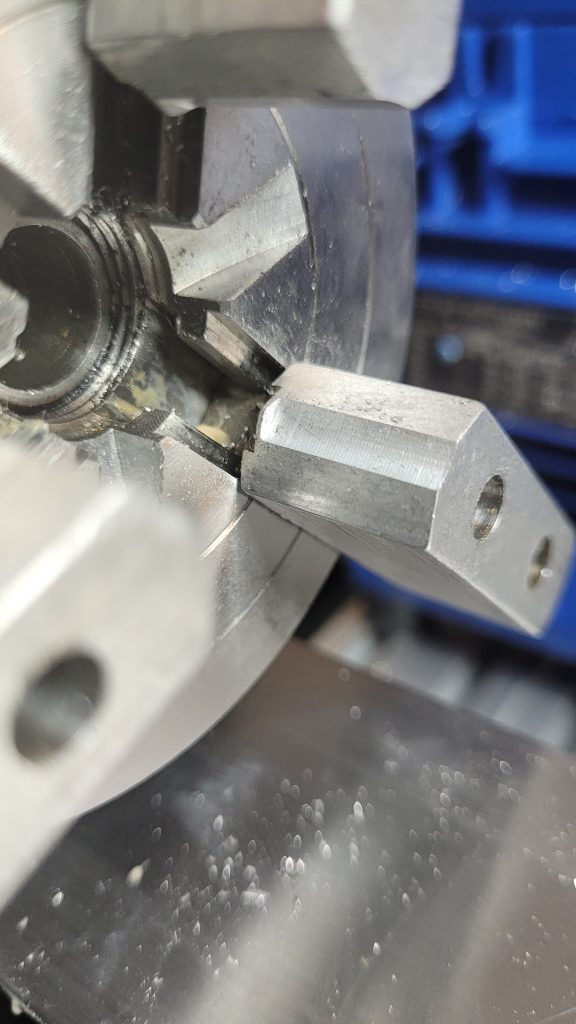

a new 3 jaw ‘self-centering’ chuck

new needle bearing center

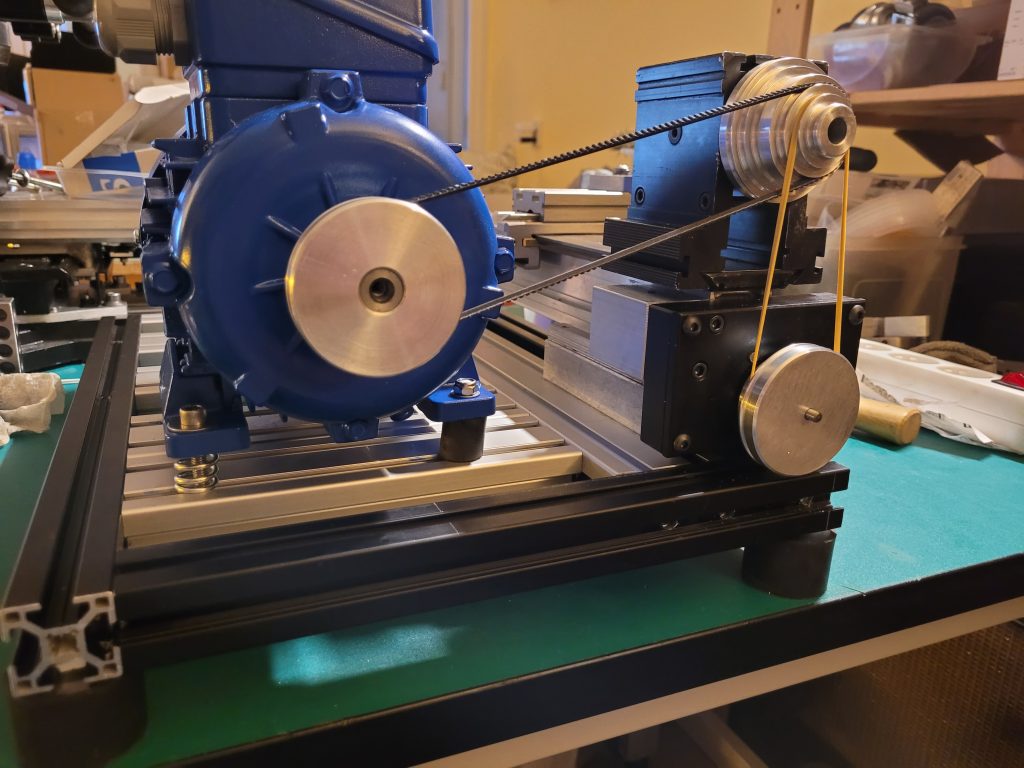

new compound slide and pulleys and belt

installed new 2RSH-C3 bearings

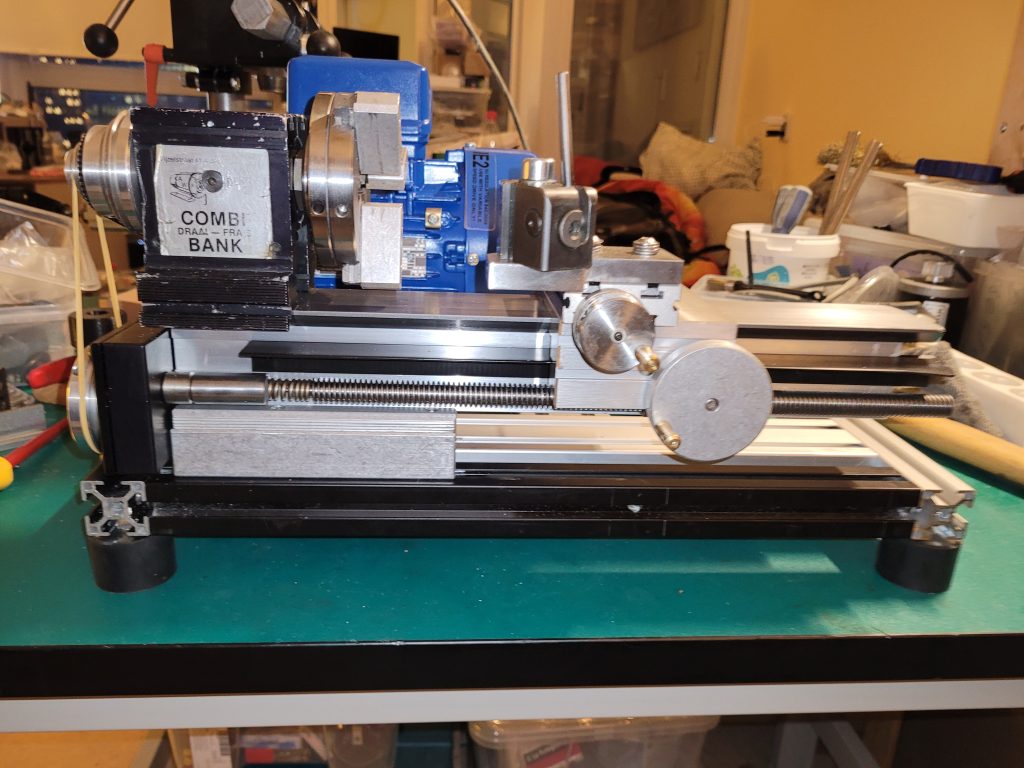

made a frame from mostly scrap alu extrusions

wired it up to 3 phase 230V

and le voila

re-used motorbike clutch springs for tensioners

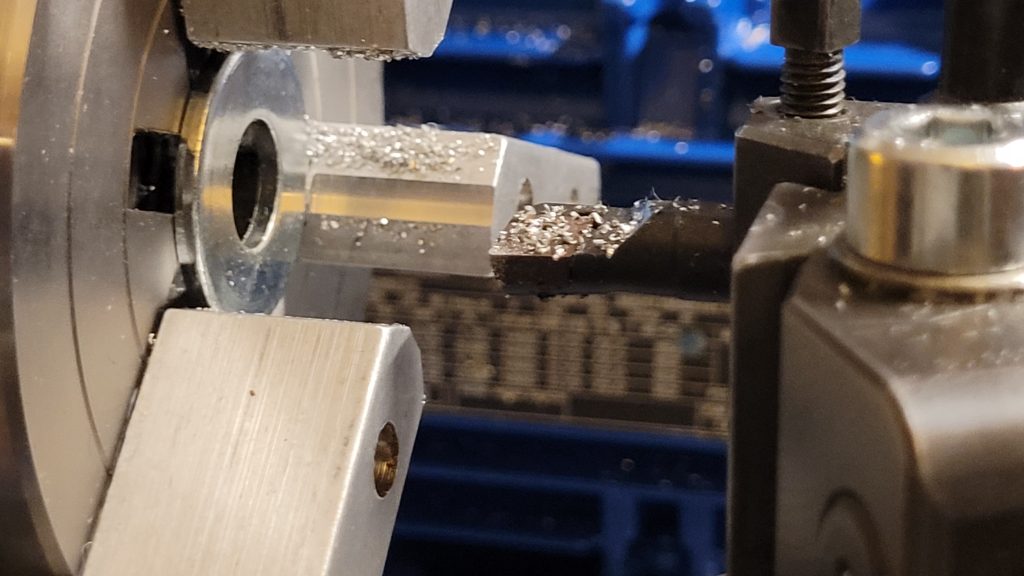

and true’d the new 3 jaw chuck

remove that lip

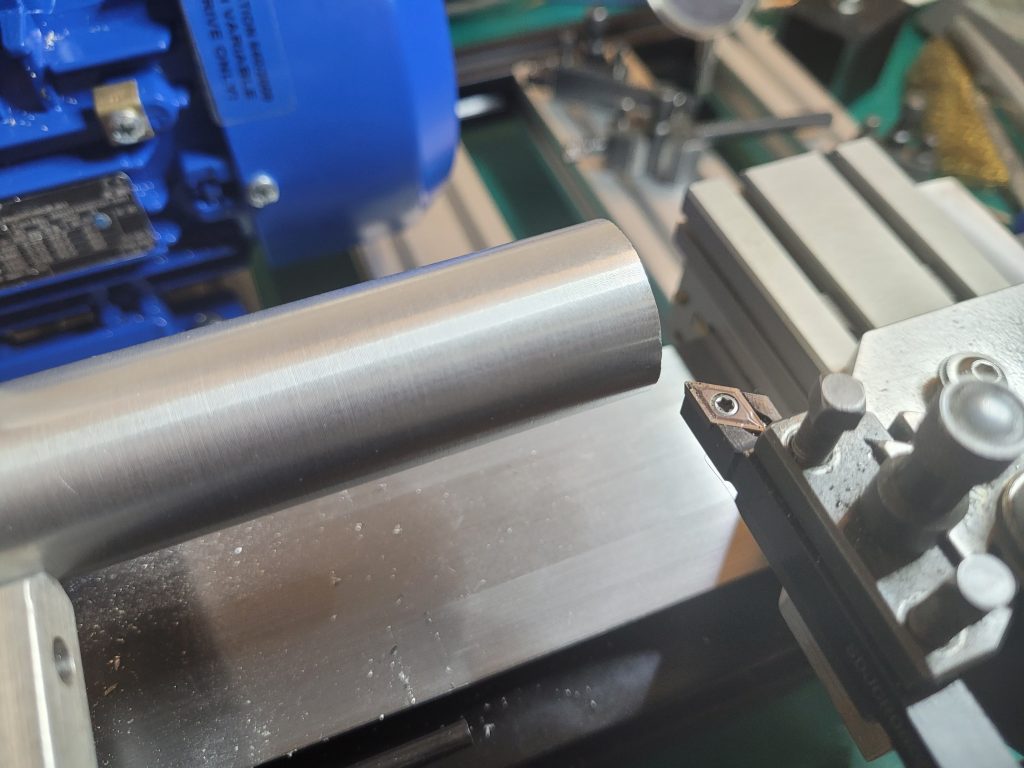

and played with some stock

facing

almost there

and done

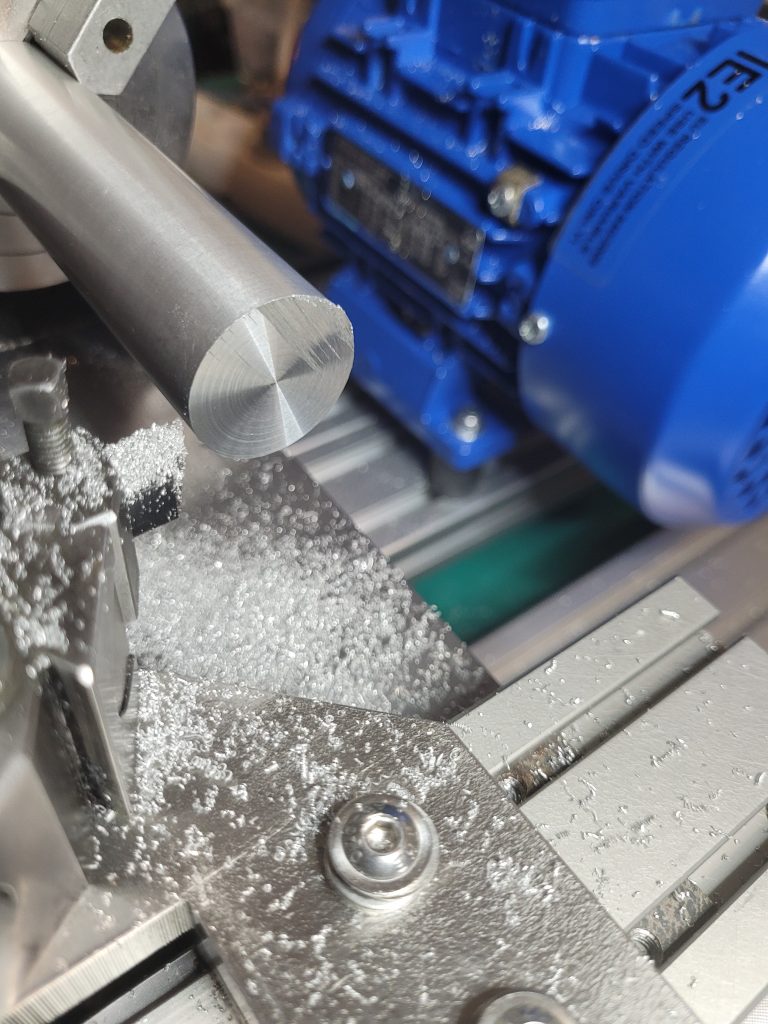

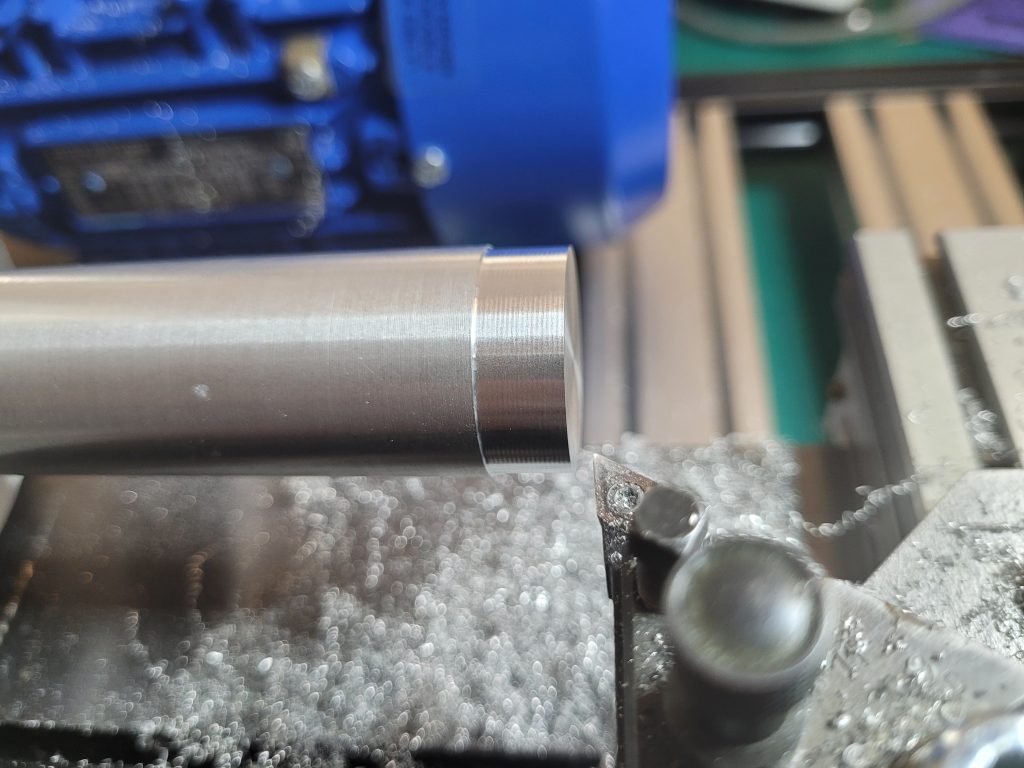

a rough pass (~18 rotations over ~9mm)

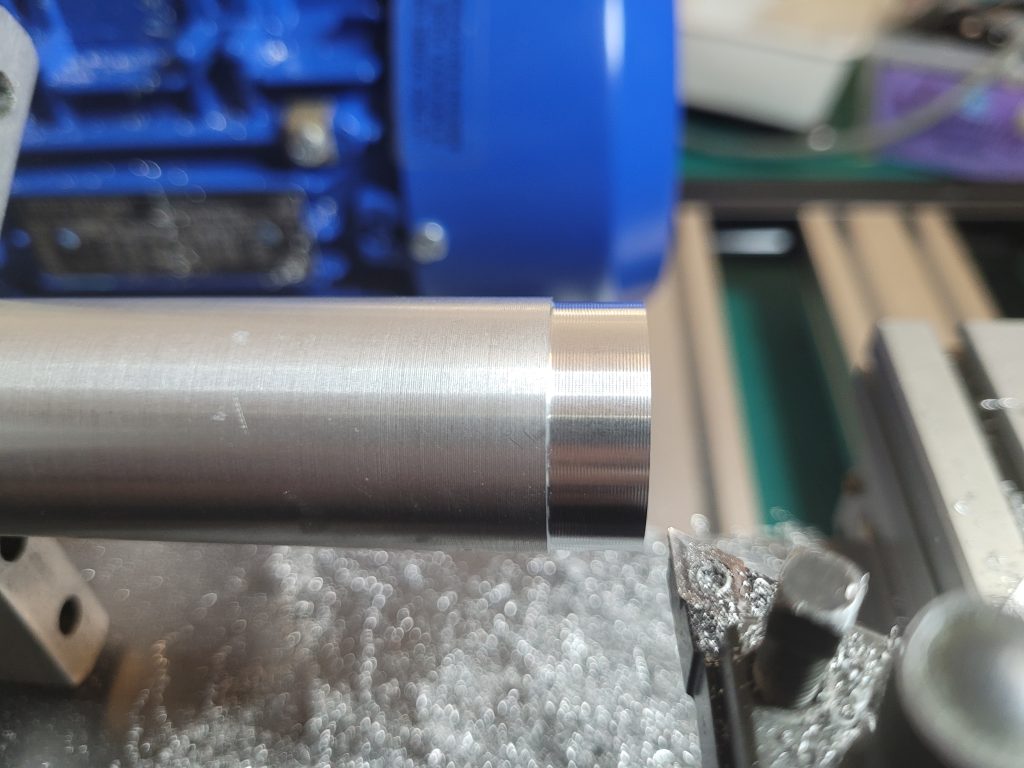

fine pass (~31 rotations over ~9mm)

spaghetti like chips